A typical engine contains hundreds of parts, none of which could function properly without oil. Far from a simple commodity, oil is a dynamic enabler of performance. It must lubricate, cool, protect, seal, actuate components and more. And it must do it all while exposed to tremendous heat and stress. Here, we highlight key areas where oil goes inside your engine and what it does once it’s there.

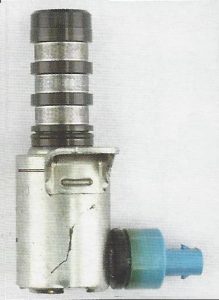

Variable Valve Timing (VVT)

To increase fuel economy and reduce emissions, most modern engines use VVT systems to adjust when the valves open and close. VVT systems use motor oil as a hydraulic fluid to actuate cam-phaser components. Solenoids, like the one shown here, control cam-phaser timing. These solenoids contain tiny openings through which the oil must flow. Even minimal varnish or deposits can disrupt the system, triggering a check engine light. The oil must maintain viscosity to junction as a hydraulic fluid while resisting deposits to maximize VVT system performance.

Valves and Seals (1)

Though not illustrated here, valve seals prevent oil from running down the valve stems. This keeps the oil on valve train components and prevents it form entering the intake and exhaust ports and burning, increasing oil consumption. The oil must condition these seals to prevent drying, cracking and leaking. The oil also helps cool the valves and control cylinder head deposits, helping prevent valve sticking.

Wrist Pins & Undercrowns (2)

Crankshaft eccentrics splash-lubricate the cylinders, wrist pins and piston undercrowns. Some engines have small nozzles that spray oil directly onto the wrist pins and undercrowns. The rapidly spinning crankshaft causes air entrainment in the oil, creating foam. If foam bubbles in the oil pass between metal parts, they collapse and cause metal-to-metal contact. The oil must contain anti-foam additives to quickly dissipate foam and detergent additives to help keep the wrist pins and undercrowns clean.

Main Seals (3)

The seals at the ends of he crankshaft keep the oil inside the engine. The oil must condition seals to prevent drying, cracking and leaking.

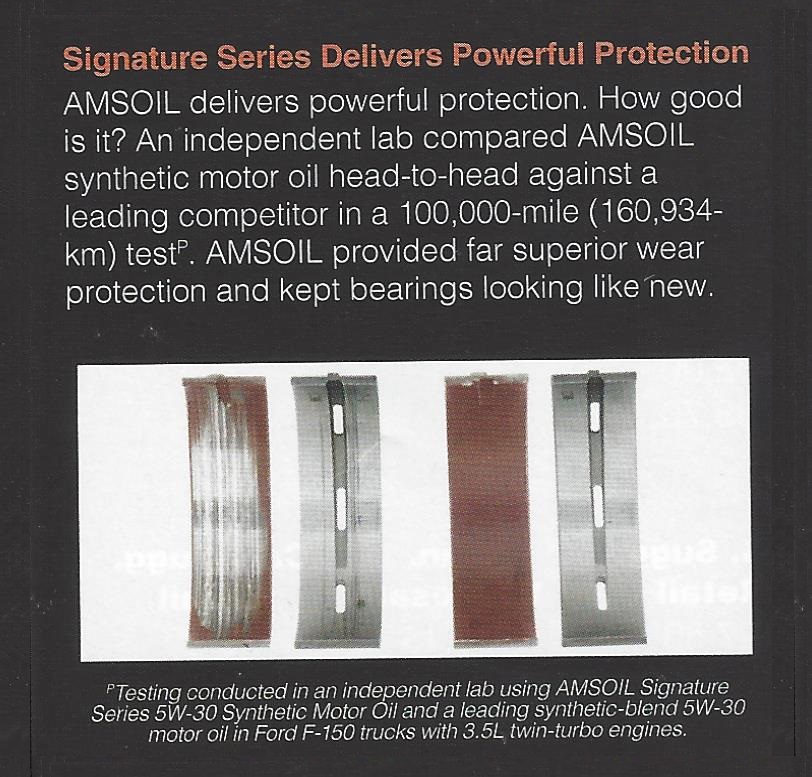

Connecting Rods & Main Bearings (4)

Combustion drives the pistons down the cylinder, creating intense pressure between the connecting rods, main journals and bearings. Oil molecules act like microscopic ball bearings that support this pressure and allow the rods and crankshaft to rotate without metal-to-metal contact. The oil must maintain its protective viscosity despite increased pressures, temperatures and shearing forces. If the fluid film weakens, the oil will squeeze from between the journal and bearing clearances, resulting in metal-to-metal contact and bearing wear.

.

.

.

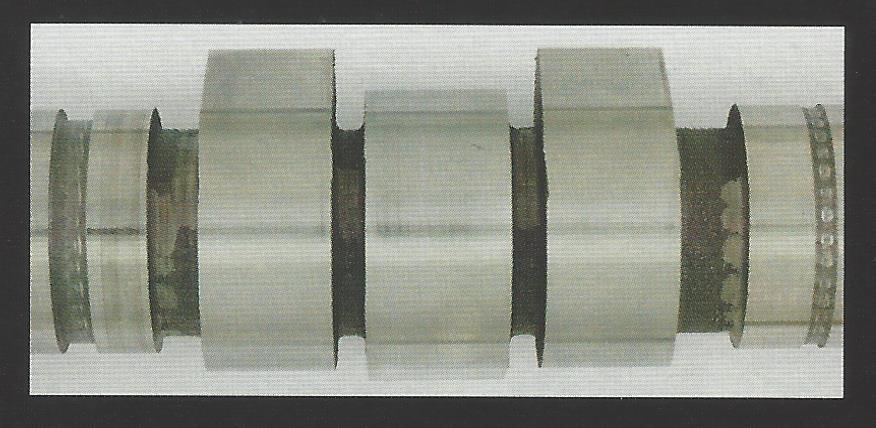

Camshaft (5)

The camshaft and lifters open and close the intake and exhaust valves. To prevent wear, the oil must form a strong fluid film that separates the cam lobes and lifters. It also must contain robust anti-wear additives to maximize the life of the camshaft and bearings. As the image shows, AMSOIL Signature Series 0W20 Synthetic Motor Oil (ASM) did an excellent job protecting against cam wear in rigorous, third party testing.

.

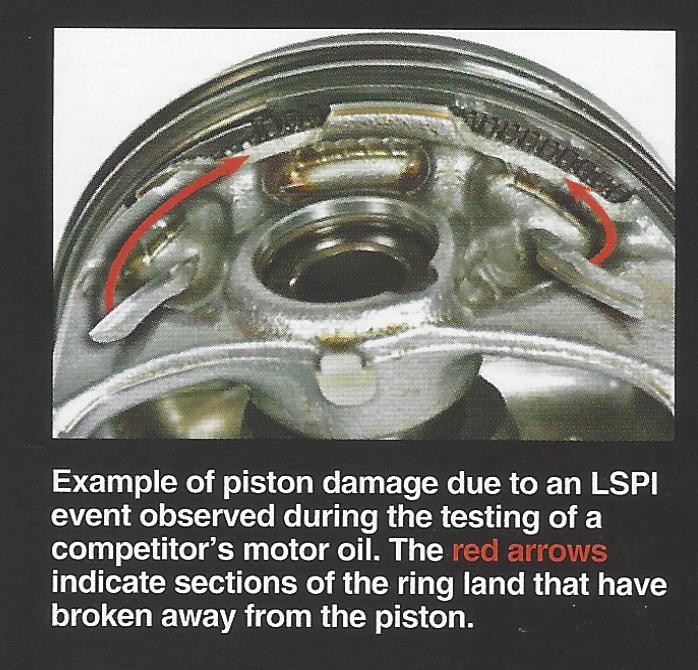

Pistons, Rings & Cylinders (6)

The pistons compress the air in preparation for combustion. The piston rings perform several critical functions: they must seal the combustion chamber, return excess oil on the cylinder walls to the sump and transfer extreme piston crown heat to the cylinder walls.

To prevent wear despite intense heat and shearing forces, oil must maintain a strong, consistent film between the rings and cylinder walls. It also must prevent deposits that cause ring sticking, increased oil consumption, compression changes and low-speed pre-ignition (LSPI).

Signature Series Synthetic Motor Oil achieved 100 percent protection against LSPI1 in the engine test required by the GM* dexos1® Gen 2 specification – zero occurrences were recorded throughout five consecutive tests.

Oil Galleries & Passages (7)

An engine contains an intricate network of oil galleries and passages that carry oil to components. Passages in the crankshaft, for example, carry pressurized oil to the rod and main bearings, while similar passages in the upper end carry oil to the valve-train. Oil that thickens in the cold can fail to flow through narrow passages and starve the engine of oil. Sludge, meanwhile, can plug passages and have the same effect. The oil must remain fluid when the temperature drops, and it must prevent sludge.

Oil Pick-Up Tube Screen (8)

The oil pump draws oil through a fine screen and pressurizes it so it can flow through the oil galleries and passages to the bearings and valve-train. Sludge can plug the screen, starving the engine of oil. Oil that thickens too much to pass through the screen has the same effect. Therefore, oil must prevent sludge to keep galleries and passages clean, ensuring maximum oil flow.

This article from the AMSOIL Dealer Magazine April 2019 edition.

1Based on independent testing of AMSOIL Signature Series 5W-30 motor oil in the LSPI engine test as required for the GM dexos1® Gen 2 specification