AMSOIL Proves Its Superiority Again . . .

From The AMSOIL Dealer Magazine April 1995

The large upper midwestern trucking company with which AMSOIL recently concluded an eight-month demonstration was interested in doubling its oil drain intervals, taking them from 20,000 miles to 40,000 miles – without compromising engine durability. They put AMSOIL Semi-Synthetic 15W-40 Motor Oil (PCO) to the test.

Scope and Mechanism

The trucking company agreed to continue using the original fill of PCO in the test vehicles, as long as spectrochemical and physical property analyses made by an independent testing facility showed the oil fit for continued service, up to a maximum of about 60,000 miles per vehicle – the extra 20,000 miles would prove PCO had life to spare at 40,000 mile drain intervals. The company also agreed to run control units with standard maintenance practices.

Protocol

The eight-month demonstration included six model year 1993 Class 8 Kenworth T600 tractors equipped with Series 60 Detroit Diesel engines. All hauled freight interstate; all were matched for odometer mileage.

Before the demonstration began the testers established baseline data, extremely conservative condemnation limits for various parameters and 5000-mile used oil sampling intervals for the six vehicles. The control vehicles would get new oil at 20,000-mile intervals. The test vehicles would keep the same oil for the entire demonstration – if the PCO was up to it.

The demonstration began after changing the six trucks’ oil. Three were filled with the fleet’s regular oil; three were filled with PCO. The vehicles traveled an average 57,670 miles.

The Oils

The control: A petroleum 15W-40 oil with 12 TBN, a viscosity of 15.31 cSt at 100°C and an honorable history of engine protection at 20,000-mile drain intervals.

The test oil: AMSOIL PCO, a semi-synthetic 15W-40 oil with 12 TBN, a viscosity of 15.32 cSt at 100°C and a remarkable record in the long drain arena.

Findings

AMSOIL PCO not only went the distance, it annihilated the control oil in performance. And, at the end of the demonstration, the PCO was still fit for continued service; 60,000 miles, after all, is just a warm-up for PCO.

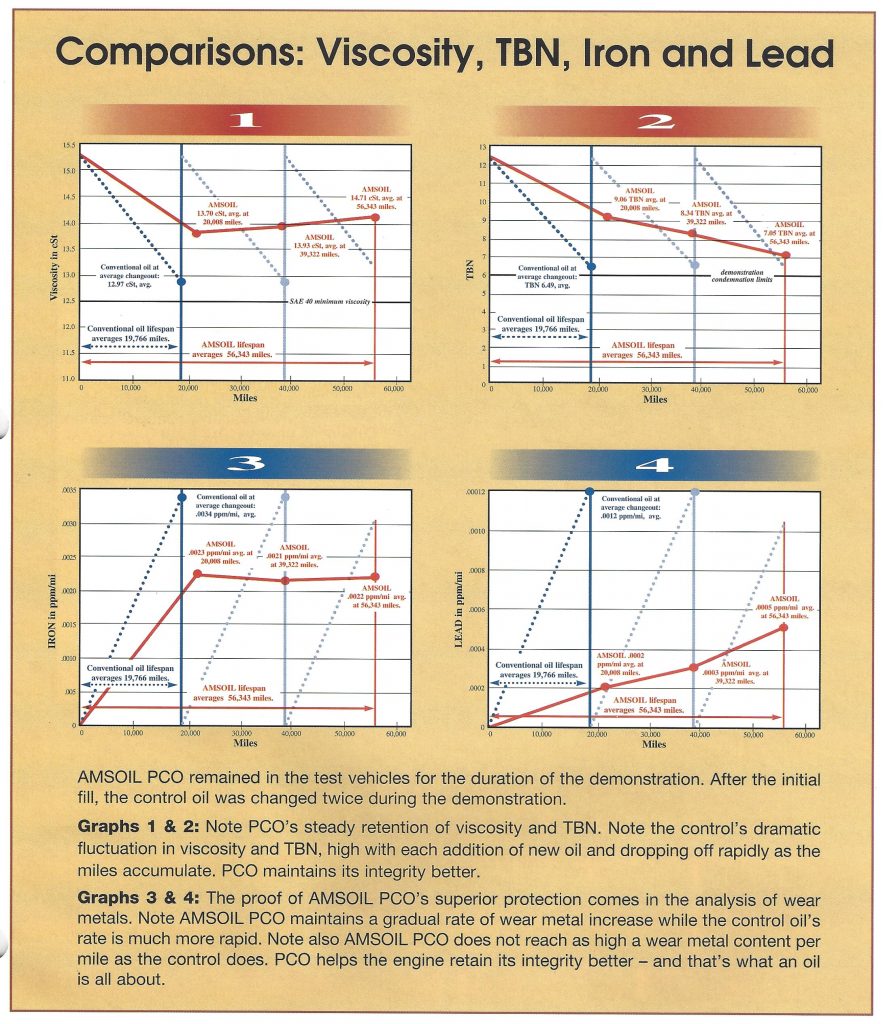

AMSOIL PCO maintained more constant viscosity than the control oil did, and so provided more consistent protection against metal-to-metal contact and wear. By losing viscosity rapidly during the first 5000 miles of service, the control oil provided good protection against metal-to-metal contact for one-quarter of its drain interval and diminishing protection for three-quarters.

In fact, eleven petroleum oil samples, 36 percent, sustained viscosity losses that changed their grade from SAE 40 to SAE 30. None of the PCO samples sustained a change in viscosity grade – even though each saw nearly 60,000 miles of service.

AMSOIL PCO maintained greater corrosion-fighting TBN than the control oil did. As with viscosity loss, the control oil lost TBN most rapidly within the first 5000 miles of service. Control engines received good protection against acid damage for one-quarter of a drain interval and lesser protection for three-quarters. Two petroleum oil samples, roughly seven percent, sustained TBN losses that exceeded the demonstration condemnation limits. None of the PCO samples exceeded TBN loss limits.

The final evidence of PCO’s superior wear control came with wear metal analysis, calculated in parts per million per mile. With PCO, average wear rates were 20 percent lower for iron and 70 percent lower for lead than they were with the control oil. Six control oils, 20 percent, exceeded lead condemnation limits.

Interpretation

How could two oils with similar TBN and viscosity values at the beginning of the demonstration provide such different service?

In a normally functioning engine, an oil’s content of wear metals steadily increases with use. Metal parts simply can’t move relative to one another without removing some surface metal. How much depends largely on oil quality. Oils with superior lubricating ability, viscosity retention and anti-wear additives keep the rate of wear metal increase low by decreasing the incidence and severity of metal-to-metal contact.

Similarly, as mileage increases, an oil’s TBN and viscosity decrease. Acids ‘eat up’ TBN chemistry. Scissor-like shearing actions in the engine cut apart viscosity index (VI) improvers, diminishing their ability to pump up high temperature viscosity. The better the TBN and VI improver additives, the more TBN and viscosity an oil retains.

Conclusion

The trucking company asked for 40,000 mile drain intervals with no compromise on wear control. AMSOIL PCO demonstrated an ability to provide improved wear control with 60,000-mile drain intervals and demonstrated that nothing compares to AMSOIL!

*All trademarked names and images are the property of their respective owners and may be registered marks in some countries. No affiliation or endorsement claim, express or implied, is made by their use. All products advertised here are developed by AMSOIL for the use in the application shown.

Reproduced With The Permission Of AMSOIL INC. All Rights Reserved.

SLS Note: In the last 25 years AMSOIL’s Synthetic Diesel Oils and filters have seen significant upgrades and the same can be said for diesel engines. In mechanically sound heavy diesel engines (with no OEM or EPA design issues) 60,000 miles could almost be considered a “Normal” change interval when using a high quality synthetic diesel oil. Add in the AMSOIL By-Pass filter system and regular oil analysis and you are looking at 100,000+ mile oil change intervals (and less wear than using regular diesel oil and 20,000 mile change intervals. So, regular oil and filter changes every 10,000 or 20,000 miles or analysis every 10,000 or 20,000 miles and a full oil and filter change when analysis says it is time to change. This saves you money on maintenance and gives you a better idea of what is happening inside your engine. It can spot potential problems long before you would know about them without the analysis giving you a chance to do preventive maintenance and saving down time and expense from a major failure. Now add in the increase in fuel economy and it’s a “No Brainer. (People will laugh at a 1% increase in fuel economy but, what does a 1% savings in your annual fuel bill equal? Probably more than you spend on oil and filters.)