Contaminants will inevitably corrupt any lubricating system, but quality lubricants considerably reduce contamination and extend oil service. There are four ways contamination occurs in lubrication systems.

- First, the system itself can generate contamination through poor system or component design, temperature-related chemical reactions or just normal use.

- Second, contamination can be caused by careless packaging or handling of components before or during installation.

- Third, contamination can be introduced though improper or careless maintenance.

- Fourth, contamination can be caused by another system leaking into the first system.

Base oils possess a varying degree of solvency (the ability to dissolve a solid, liquid or gas), which assists in maintaining internal cleanliness. However, commonly paired detergents and dispersants playa key role. These pairings maintain internal cleanliness by suspending contaminants, minimizing contaminant clumping (agglomeration) and preventing contaminants from adhering to components. Over time, degradation of the oil can result in a cleanliness issue, but oxidation inhibitors can reduce this effect.

Detergents added to lubricants minimize deposit formation in the high-temperature areas of an engine. The most used detergents in motor oil formulations are metallic (ash) soaps with reserve basicity to neutralize the acids formed as byproducts of combustion. Other detergents include metalorganic compounds of sodium, calcium and magnesium phenolates, phosphonates and sulfonates.

Dispersants are additives that help keep solid contaminants in suspension. By keeping contaminants suspended within the lubricant, sludge, varnish and other carbon deposits are prevented from forming on engine parts.

Dispersants also prevent contaminants from agglomerating into larger and potentially dangerous particles. When particles are held in suspension and prevented from agglomerating, they can be carried to the filter and removed from the lubricant.

Dirty components run poorly, pollute and don’t last. They cause system failures in engines, compressors and gear-box systems that dramatically increase downtime, increase operating costs and reduce equipment life. Clean lubrication systems, on the other hand, require less maintenance, produce more energy, use fuel more efficiently, increase equipment service life and run cleaner.

AMSOIL lubricants use detergent and dispersant additives to significantly reduce sludge and carbon deposit formation better than other oils.

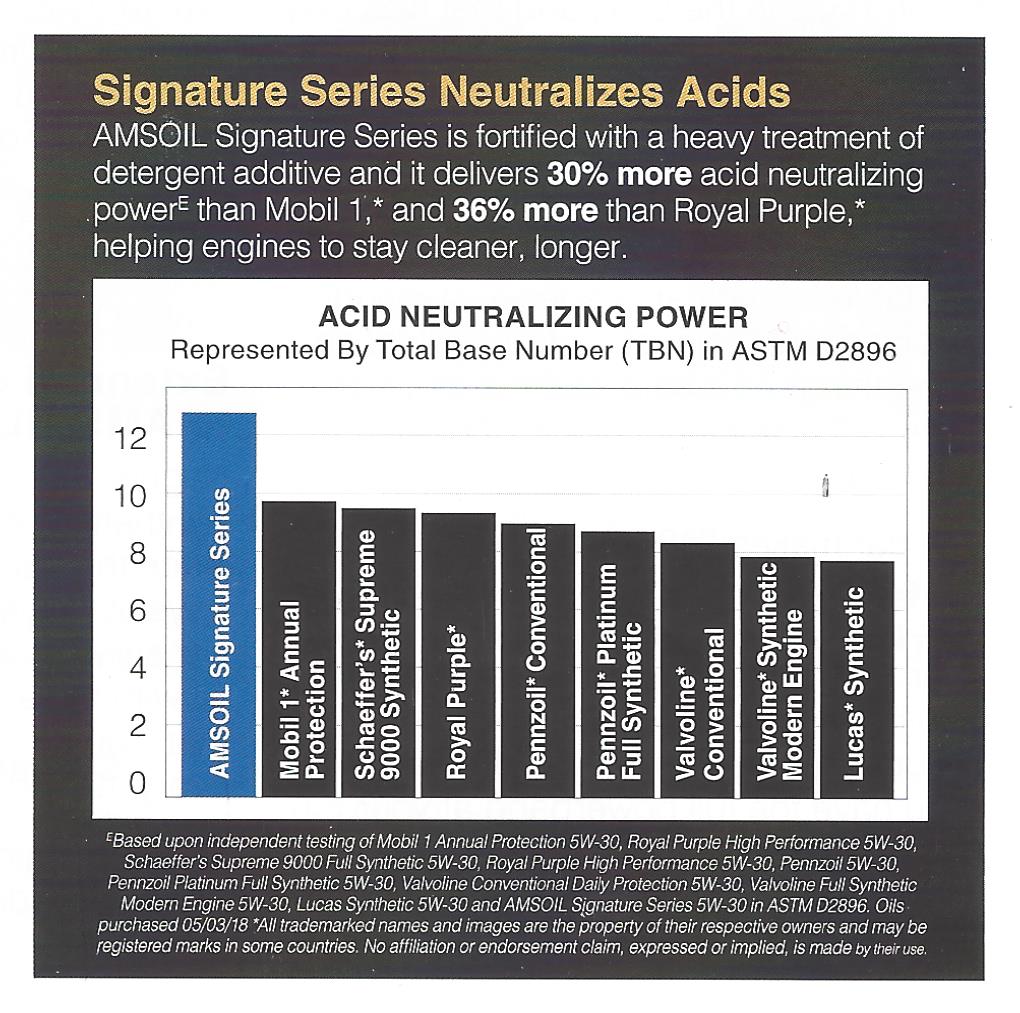

One way to know how well a lubricant can protect your vehicles and equipment is to look at the total base number (TBN), which indicates its ability to neutralize contaminants such as combustion byproducts and acidic materials. It is a measure of (alkaline) additives in the oil. Higher-TBN oils can neutralize a greater amount of acidic materials, which results against corrosive reactions.

TBN levels are targeted for the intended application. Typically, gasoline engine oils display lower TBN numbers, while diesel engine oils must manage the heavy contaminant loading from soot and sulfur and usually run higher.

TBN levels decrease as the oil remains in service. When the level reaches a point where it can no longer protect against corrosion, the oil must be changed.

Oils formulated specifically for extended drain intervals typically display elevated TBN numbers to ensure proper corrosion protection for the duration of the extended interval.

Base Number Test (ASTM D2896 / ASTM (4739)

The Base Number Test measures the detergents and dispersants in oils.

ASTM D2896 is commonly used on new oil samples and typically results in higher values as it titrates both strong and weak base materials. ASTM D4739 is frequently used on used oil samples and only titrates the remaining strong base material. The biggest difference between the methods is the type of acid used for titration.

AMSOIL Advantage

High TBN

Because AMSOIL lubricants contain consistently high TBNs, they neutralize acidic contaminants formed during the combustion process and keep these contaminants in suspension to prevent corrosion.

AMSOIL Signature Series 100% Synthetic Motor Oil

*All trademarked names and images are the property of their respective owners and may be registered marks in some countries. No affiliation or endorsement claim, express or implied, is made by their use. All products advertised here are developed by AMSOIL for the use in the application shown.

Reproduced With The Permission Of AMSOIL INC. All Rights Reserved.